Project Highlights:

- The project covers the design, engineering, procurement, fabrication, quality assurance, packing, and shipping of 79 shop-fabricated stainless-steel tanks and standpipes.

- All engineering design is being carried out in Australia, while drawing drafting and fabrication taking place in India, ensuring compliance with Iluka specifications and Australian standards.

- Quality control is being ensured through ISO 9000 certified systems, supported by Access Petrotec’s own QA/QC inspectors and third-party agency TUV India.

- All materials used are traceable to EN 10204 Type 3.1 certifications, with proper marking and storage protocols to maintain quality and traceability.

- The tanks and accessories will be packaged with shrink wrapping, crating, and labelled according to transport drawings and shipped FOB from Indian ports (Mumbai or Mundra).

- The project is managed by a joint team from Australia and India, with a dedicated project manager, principal engineer, and expeditor overseeing all aspects of execution.

- A detailed project execution plan and risk matrix have been developed to address potential risks including schedule delays, material supply issues, and quality concerns.

- Key success factors for the project include safety, regulatory compliance, on-time delivery, adherence to budget, and enhancement of company reputation.

Project Description:

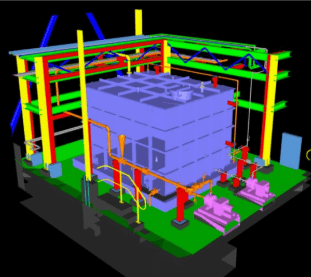

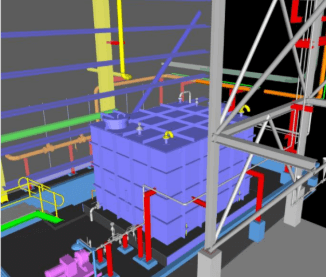

Access Petrotec and Mining Solutions is progressively building 79 large tanks in SS and Duplex SS materials. Our work includes design, detailed engineering, procurement and fabrication of the Stainless-Steel tanks and standpipes & associated components including the roof, floor, shell, nozzles, manways, baffles, openings, overflow box, vent pipe, hatches, manways, cleanout ports, D-doors and support attachments etc.

These tanks are being built in compliance with API 650, API 620, ASME Section IX & other relevant Australian Standards.

Access Petrotec is poised to deliver 79 tanks in record time of 12 months from the date of award.

Project Deliverables:

- Supply of 79 shop-fabricated stainless-steel tanks and standpipes, divided into ten separable portions with detailed equipment schedules.

- Design and engineering of tanks performed in Australia using software such as AME Tank and ANSYS, in compliance with API 650 and API 620 Standards while rectangular tanks are designed using Roark’s formulae.

- Procurement of materials (plates, pipes, flanges, structural steel) from approved vendors, with full traceability and certification to EN 10204 Type 3.1 standards.

- Fabrication in India using dedicated stainless-steel processes, with qualified personnel following ASME IX and API 650/API 620 standards.

- Surface treatment including pickling and passivation of stainless-steel components.

- Quality assurance package including Inspection and Test Plans, WPS/WPQR, NDT procedures, and PMI reports, supported by in-house and third-party inspectors.

- Manufacturing Data records as required per AS standards

Project Information

- Categories: Fabrication

- Client: Iluka Rare Earths Pty Ltd

- Type: Shop Fabricated Tanks – 79 Nos m2

- Completed date: Ongoing

- Location: Eneabba Townsite, WA