Project Highlights:

- Successfully implemented vent system solution resulted in increased production by 50% and achieving BHP Billiton’s goals of increased plant throughput

- Analysis of the existing vent system on-site to determine operating data

- 3D Scanning of the existing venting system

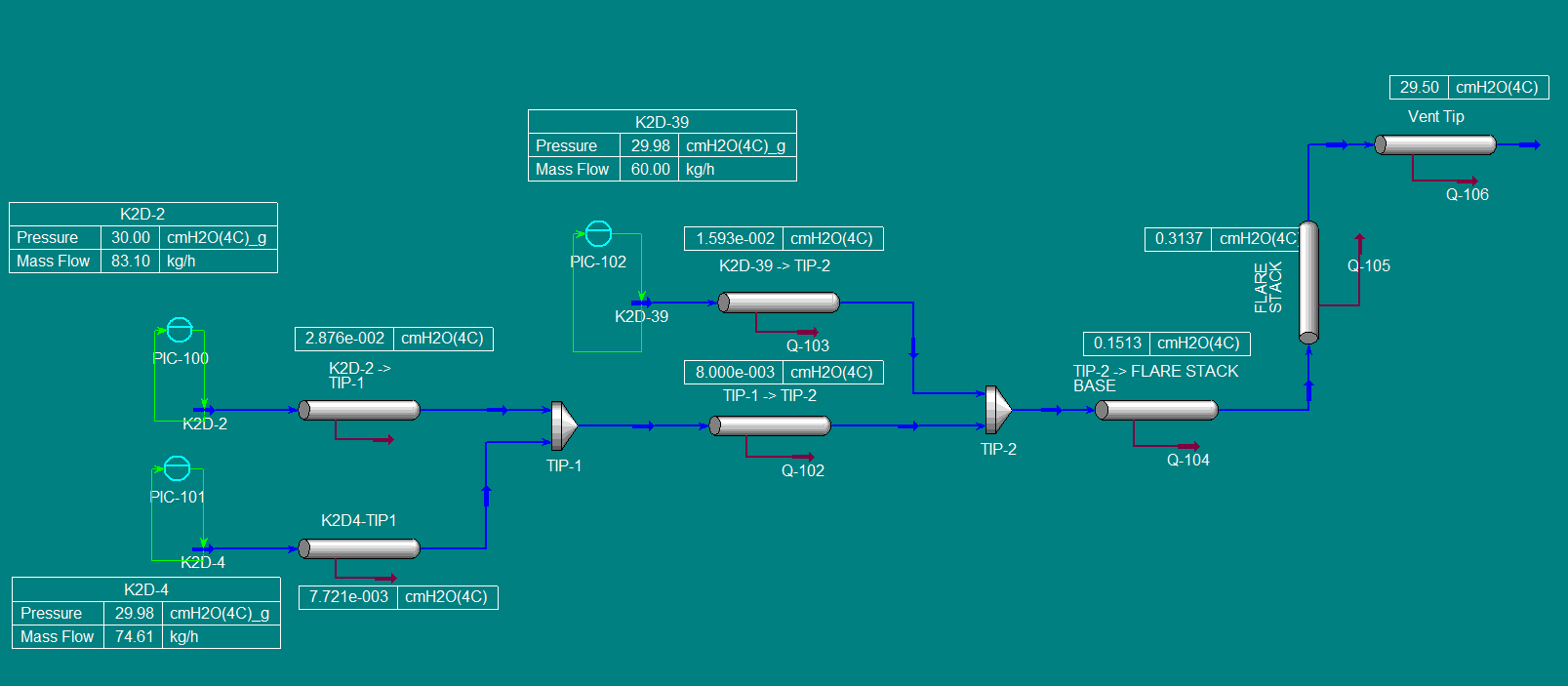

- Process Modelling via HYSIS simulations performed to evaluate optimal solution

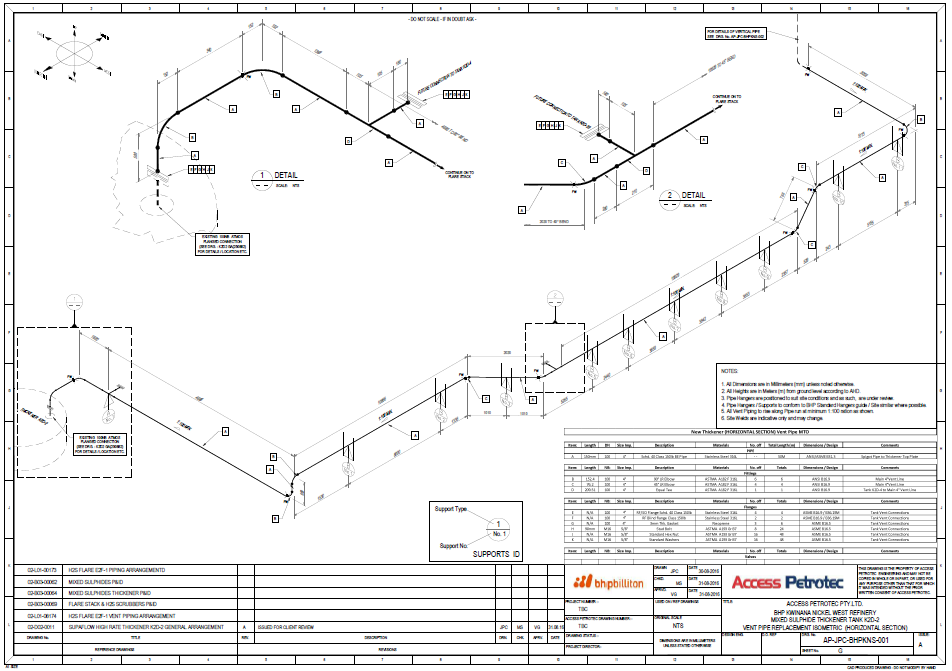

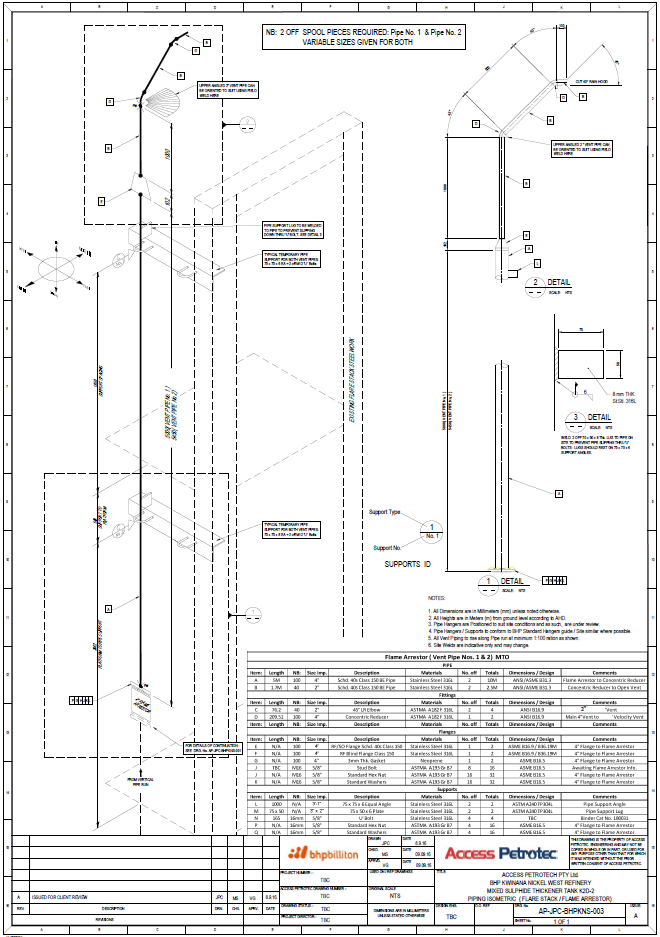

- Design and Engineering for installation of new vent lines

- Design drawings were created for new vent lines

- Solution was implemented and solved the existing throughput problems

Project Description:

The BHP Nickel West Kwinana Nickel Refinery (BHPKNR) located in Kwinana operates the tanks K2D-2, K2D-4 and K2D-39 which vent excess Hydrogen Sulphide (H2S) gas through a 2” cold vent piping network. The Nickel refining process requires H2S gas to be injected upstream of K2D-2 and any un-reacted H2S is vented primarily through K2D-2 with additional venting from K2D-4 and K2D-39 tanks. The Nickel refining process requires a maximum flowrate of 175Sm3/hr of H2S at 50°C to be injected upstream of K2D-2.

In order to increase the Nickel processing throughput of the refinery, the quantity of H2S injected needed to be increased. However, the piping network through which the excess H2S was vented was sized for a lower throughput and acted as a bottleneck in the existing operation.

Back pressure in the K2-D4 and K2-D39 tanks was higher than 450mm WG that the seal pots were designed was resulting in bubbling of gas from the seal pots. The bubbling of the H2S through the tanks had the potential to create highly hazardous environment for operation and maintenance personnel.

In view of above concerns, BHPKNR have engaged Access Petrotec with the task of reviewing the existing vent network and recommending a solution to overcome this safety hazard.

Project Deliverables:

1 Site Analysis and Vent System Review

Access Petrotec carried out a complete review of the entire vent system on site to ascertain operating parameters and site constraints. 3D scanning was also performed to allow for design and determination of optimal placement of a new vent system.

2 Engineering, Design and Process Modelling

After ascertaining operating parameters and constraints, various process scenarios for the vent system were simulated using HYSIS software to determine the optimal design for the new vent system. The optimal solution was to install two new vent lines; one connecting thickener tank K2-D2 and another connecting downstream tanks K2-D4 and K2-D39 which would run alongside one another to the flare stack for venting. Once the design was confirmed a new vent system was proposed and in conjunction with 3D models obtained, detailed drawings for two new vent lines were created to implement the design.

3 Implementation of New Vent System

After isometric drawings and design was completed, BHP Billiton implemented the new vent system to replace the existing system. The results showed that back pressure on the K2-D4 and K2-D39 tanks was reduced and seal pots no longer bubbled gas. Additionally, the flowrate through the new vent system significantly increased allowing for approximately 50% increased production.

Project Information

- Categories: Facility Engineering and Design

- Client: BHP Billiton Nickel West, WA

- Type: Ventilation System Study

- Location: Kwinana, WA