Project Description:

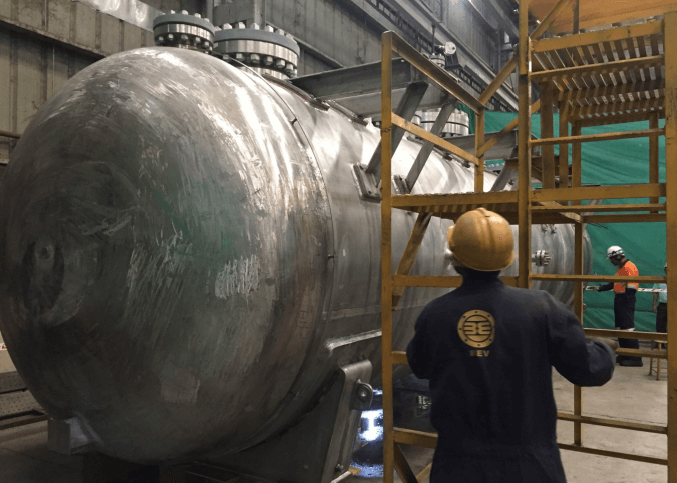

BHP Billiton observed thinning of H2C-8E Autoclave walls in July 2016. As a result, regulator insisted to replace the Autoclave in a shortest possible timeframe. Necessary financial approvals were in place by end August to place the order in first week of September 2016. BHP Billiton was looking forward to a cost-effective fabricator who could fabricate this Autoclave in record time of 6 months. Access Petrotec took up the challenge and delivered the fabricated and tested Autoclave in the record time of 5 months to BHP Billiton nominated freight forwarder in India. Later one more Autoclave was added to the order for the expansion of their Kwinana Nickel Refinery. Due to urgency of the vessel and BHP deputed resident engineer in our facilities for the duration of the project and the factory worked 24X7 to deliver the first Autoclave by due date.

Project Deliverables:

1 Detailed Engineering Design

Access Petrotec carried out detailed engineering design in compliance with the latest AS1210 standards. Third Party verification was carried out to check Access Petrotec design calculations and then the design was registered with WorkSafe, Australia.

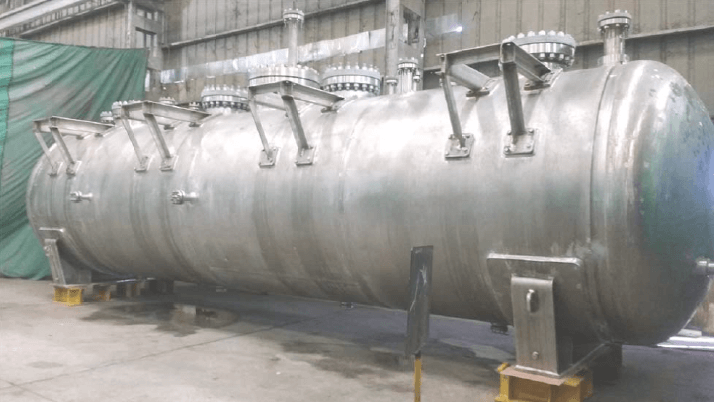

2 Fabrication and Supply of Equipment

Access Petrotec airfreighted 35 tons of Super Duplex plates and nozzle forgings from Europe and Korea to reach our fabrication facilities in Baroda, India in 3 weeks from the date of award and the factory worked day and night to deliver the first Autoclave in 5 months from the date of award and the second one followed 3 months later.

3 Documentation

Manufacturing Data Records (MDR) of both vessels were prepared in compliance with AS 4458 and BHP Billiton Standards for registration with Department of Mine & Petroleum (DMP).

Project Information

- Categories: Fabrication

- Client: BHP Nickel West

- Type: Nickel Reduction Autoclave H2C‐8 E and H2C‐8‐H for Replacement and Expansion of Nickel Refinery m2

- Location: Kwinana, WA