Summary:

- Supply of various types of pumps for BHP Billiton Kwinana Nickel Refinery

- Ammonium Sulphate Slurry Pump (Rubber Lined) & Motor

- Nickel Slurry Dredger Pump

- Bare Shaft Centrifugal Pumps & Mechanical Seals

- Submersible Sump Dredger Pumps

Project Description:

BHP Billiton transports Sulphuric Acid from Kalgoorlie Nickel Smelter to Coogee Chemicals in Kwinana via rail mounted acid containers. These containers are unloaded at Coogee Rail terminal via pneumatic air. This pneumatic air is supplied by 2 CSX75 Sullair Air Compressors. There no was dryer installed at Coogee Terminal resulting in the corrosion of the Sulphuric Acid containers.

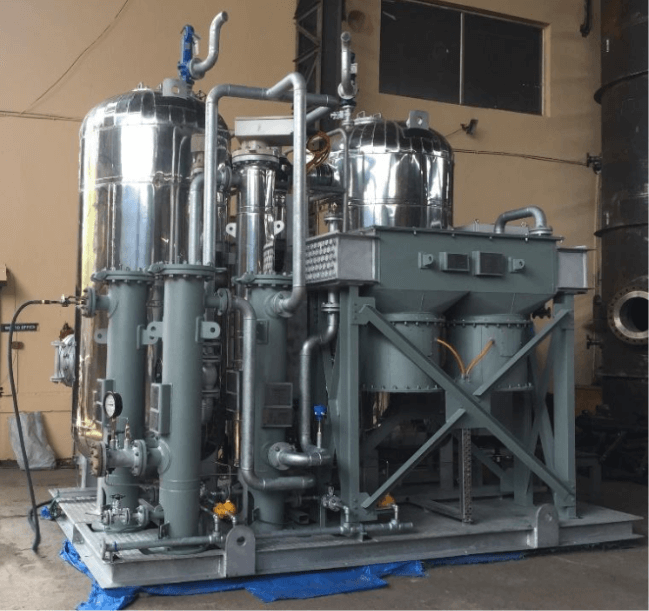

Access Petrotec simulated the mole fraction of water in fully saturated air at 53°C and simulations reveal that 22.45kg/hr of water will have to be removed from the air. Access Petrotec delivered a purge-less split flow air dryer to remove the required moisture from the air.

Project Deliverables:

1 Detailed Engineering Design

Access Petrotec carried out detailed engineering design in compliance with the latest AS1210 standards.

1 Fabrication and Supply of Equipment

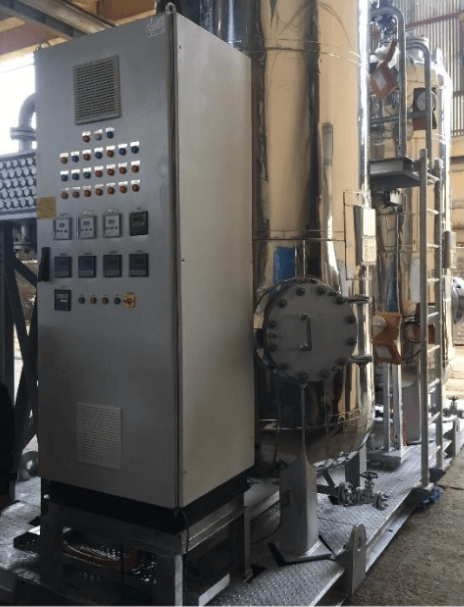

Fabrication of the skid mounted air dryer carried out at facilities in Faridabad (Delhi), India in compliance with AS1210 and AS4458. A Siemens S7 200 Programmable Logic controller was also integrated with the skid

1 Documentation

Manufacturing Data Records (MDR) of the air dryer skid were prepared in compliance with AS1210 and AS4458.

Project Information

- Categories: Equipment Supply and Installation

- Client: BHP Billiton / Coogee Chemicals

- Type: Air Dryer for Sulphuric Acid Unloading Facility m2

- Location: Kwinana Refinery WA